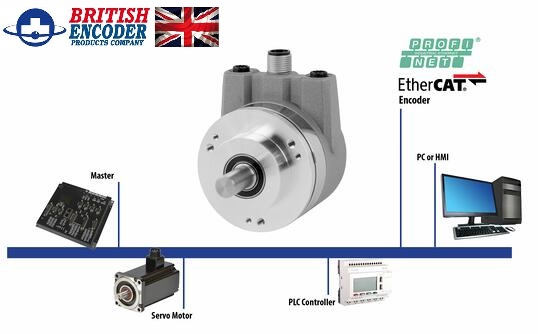

BEPC’s Absolute Encoders now with PROFINET

As more and more industrial applications switch to Industrial Ethernet, components need to keep up with the technology. That’s why EPC is now offering AbsoluteEncoders with both EtherCAT® and PROFINET® communication protocols.

EPC Model A58HE and Model A58SE are Ethernet-ready, multi-turn absolute encoders designed for harsh factory and plant environments, and are available with EtherCAT or PROFINET communication protocols. They are particularly suited to applications where Ethernet-based connectivity is required, and the encoder has to retain absolute position information after power-off events.

The Model A58HE is a 58 mm encoder in a blind hollow bore construction offering bores sizes up to 0.375″ or 15 mm and an IP65 seal. The Model A58SE is a 58 mm shaft encoder, offering a synchro flange or clamping flange, with heavy-duty and compact options, shaft sizes up to 0.375″ or 12 mm, and an IP65 seal.

“Both the Model A58HE and the Model A58SE encoders are easily designed into a wide variety of applications,” says Sarah Walter, electrical engineer, and EPC Technical Applications Manager. “And with the new heavy-duty model and the new compact model – which is the most compact unit available on the market – they are incredibly versatile mechanically. What really sets our encoders apart, however, is the high accuracy. These absolutes will give you accurate motion feedback, every time.”

The Model A58HE and Model A58SE Absolute Encoders offer:

- EtherCAT Deterministic Communication or PROFINET Communication

-

.png)

- Multi-turn resolution up to 43 bits

- Single turn resolution up to 16 bits

- 58 mm diameter housing

- Bores size up to 0.375″ or 15 mm

- Shaft diameters up to 0.375” or 12 mm

- Durable magnetic technology

- Proven turns counting technology with no gears or batteries

- Operating temperature range of -40° C to 85° C

- Sealing rating of IP65

- Continuous digital position monitoring

- Ability to retain the absolute position after a power outage

- Meet CE/EMC Standards for Immunity and Emissions

- Work in various configurations, including bus, ring, and star configurations that can continue communication in event of a line break

EtherCat-ready Absolute Encoders

EtherCAT-ready absolute encoders Model A58HE (hollow bore) and Model A58SE (shaft) are designed for harsh factory and plant

environments. Easily designed into a wide variety of applications, these encoders plug directly into a network with minimal

prerequisites, and work in various configurations, including daisy-chaining and redundant-ring configurations that can continue

communication in event of a line break. The A58E series encoders work with CANopen over EtherCAT, so for users familiar with

CANopen technology, implementation will be straight forward. As absolute encoders, they retain absolute position information even

after a power loss, facilitating speedy system recovery at start-up without the need for system re-homing.

FEATURES:

EtherCAT Deterministic Communication: CoE, FoE, EoE

58 mm Diameter Package

Shaft Unit with 2 Mounting Options

Durable Magnetic Technology

Multi-Turn Absolute Encoder (16 Bit ST /43 Bit MT)

Proven Turns Counting Technology, No Gears or Batteries

Flex Mount Eliminates Couplings and Is Ideal for Motors or Shafts

Meets CE/EMC Standards for Immunity and Emissions

Works in Various Configurations, Including Daisy-Chaining, and Redundant-Ring Configurations

Programmable Incremental

BEPC’s programmable encoders are specifically designed for the challenges of an industrial environment. But don’t let their tough

exterior fool you – contained within the rugged, industrial housing is an advanced set of electronics that allow the encoders to

be programmed to your exact application needs. Using BEPC’s optional programming module, users may select from 6 different

output types, choose from 32 different waveforms, and program any resolution from 1 to 65,536 PPR – that’s 262,144 counts using

4x quadrature counting. These programming features allow a single encoder to be configured for multiple applications, enabling one

encoder to replace many different part numbers, providing cost savings on inventory and down-time replacement. BEPC’s encoders

can also be configured and shipped with specs pre-programmed, no on-site programming needed.